Modern-day retail stores are showing an increasingly strong tilt in favor of personalized display cabinets and store fixtures. Millwork shop drawings help manufacturers to achieve laser-sharp precision required for high-level of personalization.

Retail store interiors are critical to enhancing customer experience and creating higher engagement value. Significant time and efforts are invested by architects and interior designers in planning store layout and perfecting fixtures.

Retail store furniture encompasses doors, windows, transoms, display cabinets and cases, sidelights, moldings, trims, flooring, wall paneling, crown molding, retail display fixtures, and cabinetry for store designers. But the most critical products are glass cases and display cabinets as they are the primary point of interaction with customers.

High quality millwork drawing services executed with meticulous detailing is key to achieving perfection and seamless manufacturing for retail cabinets.

How well-crafted cabinets enhance retail store interiors

Designs for retail store cabinets are blended with right amount of aesthetics and engineering principles. Detailed millwork drafting developed from architectural floor plans transfer accurate design intent to shop floor and ensure that store interiors meet the architectural vision.

The right cabinet drawing services will help retail furniture manufacturers achieve enhanced:

- Space utilization: Wall-mounted cabinets save huge floor spaces. They allow stacking the products and accommodate more number of items for display.

- Architectural theme: As themed store culture for retail brands increases, more architects embark upon designing theme-specific interiors. Designer cabinets facilitate changing look and feel of the store, and are extremely useful during theme refurbishment.

- Ergonomics: Display cabinets and glass cases offer easy access to places and better maneuvering across the shop space. Glass cabinets are easy to clean, maintain, and replace, and come cheap as compared to metal cabinets.

Challenges in creating perfect cabinets for retail stores

- Setting up a retail store with all fit-outs and furniture is a costly business;

- High cost of establishing a store at a prime commercial location where spaces are shrinking;

- The transition from design to manufacturing stage is iterative which adds to project cost.

So, once the store space is available, the immediate need is to quickly conceptualize, create custom designs, and develop cabinet shop drawings. These drawings will resolve the limitation and address every need of furniture designer, architect, store owner, contractor, as well as manufacturer.

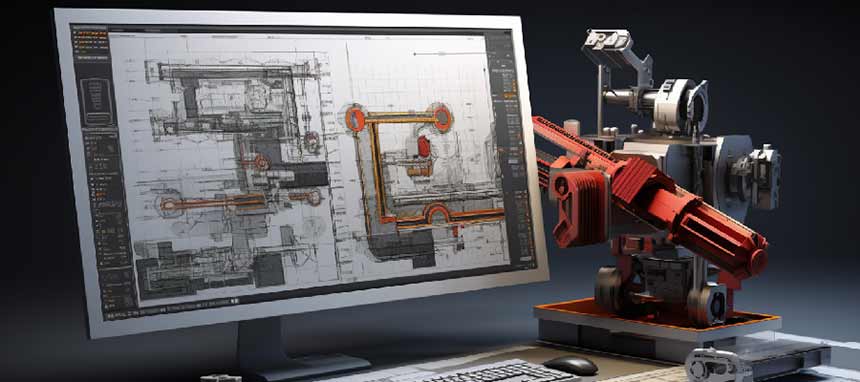

Millwork rides on smart CAD platforms for quality cabinets

Millwork furniture such as display cabinets, store fixtures, and glass cases are typically custom made and are machined as per the need of the retail store. Finalized designs are shared with drafters to develop drawings and models for design intent communication across the teams. CAD engineers then develop initial drafts which are then revised and updated as per the architects’ and manufacturer’s viewpoints.

The process, clearly, is iterative and lengthy. It calls for detailed millwork drafting, preferably by a CAD expert, to avoid missing the deadlines and meet quality benchmarks. Adopting CAD solutions for millwork drafting helps streamline the manufacturing process by providing structured workflows.

The key advantages of millwork detailed drawings for retail store cabinets include:

1. Options for interoperability and robust project management

Parametric CAD platforms enable you to exchange millwork and cabinet shop drawings across multiple CAD platforms and ERP platforms. Such interoperability allows seamless design data exchange between teams and complete information about the product at one place.

Manufacturers can map client’s information to their 3D design models, 2D drawings, and nomenclature for manufacturing data of each cabinet or each glass case. This develops an environment to manage millwork drawings knowledge across the board – from an engineering, production, and sales perspective.

What’s more interesting is the ability to use part drawings directly from CAD library and build a completely new millwork assembly. For example, a cabinet door or a handle drawing/model once saved in the library can be reused to build an entirely new cabinet.

2. Seamless design customization and manufacturing assistance

CAD-based drafting solutions for millwork have proven to be very efficient. Especially in case of the furniture industry where new designs normal, development stages are iterative. And parametric feature handles the overall design changes very accurately when one dimension is changed.

Manufacturing shop drawings are created only when the designs are finalized to reduce change orders from shop floor. And with CAD it is possible to deliver custom products in record time by eliminating errors up to 100%.

CAD platforms allow you to develop technical drawings for millwork and installation guides to assist the onsite workers during assembly and installation. This gives you an edge over unassisted site work and any process challenges can be resolved quickly.

3. Integrated configurator for millwork CAD workflows

CAD configurator helps customize designs to create bespoke cabinetry drawings that can directly be absorbed into the display case production. A pre-validated logical rules-based algorithm engine integrated with CAD systems creates customer-specific designs and eliminates design errors.

Impact of CAD configurator on millwork projects:

- Millwork floor managers need not invest time in creating new customized CAD drawing every time. This enhances the millwork project timelines by reducing lead time up to 70%.

- Especially for glass cases, costly design errors that cause to damage the product are avoided. You can reduce the product costs by eliminating wastage of materials.

4. Shop drawings automation with CAD-based processes

With CAD, millwork drawings once created can be reused several times by capturing design intelligence to enhance the productivity of the designer. Such a set up offers accepting customers’ bespoke design requirements even at short notices and delivering final customized products.

In case of retail store display cabinets, design specifications vary from order to order. Using CAD based automation manufacturers can easily handle challenges in millwork shop drawings for cabinets and millwork drawings for glass cases.

Automation experts use macros and custom scripts to automate quality checks and validate drafting processes. This helps flagging any errors and missing data in drawings at early stages, which otherwise would create big hurdles if remain unnoticed.

Benefits of CAD-based process automation:

- Designers can populate the design specifications for display cases onto the CAD software’s rules engine using user forms

- User can have personalized designs for cases as per their store requirement without technical team’s intervention

- The automated manufacturing process driven by logical workflows is error-free

- Automated tools eliminate the repetitive design process by auto-generation of modeling and 2D drawings to save time

- Manufacturing drawings and custom BOMs generated are error free and 100% accurate

Hitech Engineering Services – An extended design arm for millwork CAD drawing and drafting services

Hitech Engineering Services, a leading millwork CAD drafting service provider, helps you achieve these benefits for your store. Right from design drafting, synthesis, and space optimization of display cabinets and glass cases for retail stores, our millwork experts virtually act as an extended arm to your design teams.

Whether you are planning your next retail store or enhancing your present store decor to enrich shopping experiences, it is best to outsource millwork shop drawing services. At Hitech Engineering Services, we have the right mix of creativity and product engineering capabilities to help you build bespoke millwork display cabinets. Get in touch with us today!

Leave a Reply