Table of Contents

Building construction projects often involve a significant amount of work that concerns millwork and cabinet makers especially in a residential or an office project. Everyone involved in the project, the furniture designer, millwork developer, and the architect, all of them have different opinions about designs and final fabrication calls.

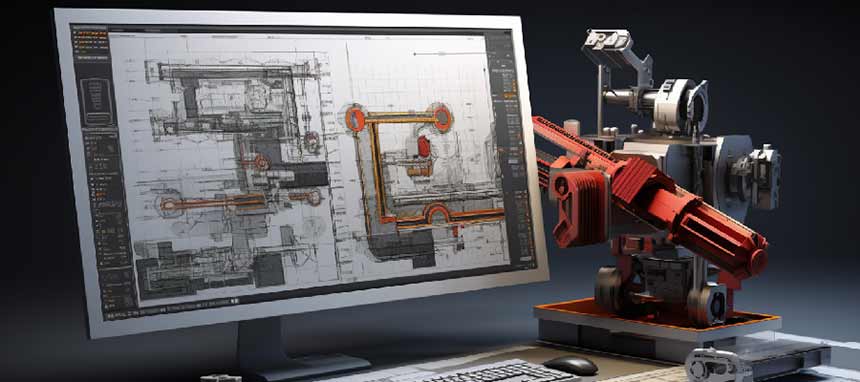

Casework or cabinets embedded as a part of the building need attention to all the details warehoused within the shop drawings. Designers or CAD drafters need to provide, enough information to carry out uninterrupted information.

Why is it difficult to come to a consensus for casework shop drawings?

When CAD draftsmen are working as an outside entity on a building construction project, there are a lot of opinion differences between architects and drafters. On an ideal casework project, for a large residential project, there will be more than one casework contractor working. Each of the resources producing casework drawings differ in adding the details and level of information annotated within drawings.

Also, when CAD drafters or drafting company for millwork is on a project with the construction firm, the architects insist to include the details according to their own needs. These are mostly related to the inclusion of details in the drawings which should ultimately not create issues to architects on later stages. As long as the projects are simple, these discrepancies and differences of opinions aren’t troublesome. But as the project gets larger, challenges grow bigger.

Establishing a standard practice

To standardize the process of any casework or millwork furniture design communication and manufacturing information, standards like AWI, NBKA, NFC or any other convenient standard is adopted. The shop drawings developed by drafting teams that adhere to these standards establishes uniformity across organizations and cross-organizational platforms.

The most common method of demonstrating shop drawings is to bring everyone on the same page. It is generally done by incorporating details in the drawings that can easily illustrate the manufacturing, assembly and construction methods.

Benefits of millwork or casework shop drawings

A mere adherence to standards does not solve the issues. There have to be initiatives from the CAD drafting companies, architects, furniture designers, and the cabinet makers or millwork developers.

Enlisted are a few benefits that need to be incorporated while developing shop drawings to avoid ECOs from the shop floor and reduce waste.

Conflict resolution

Drafters interpret detailed architectural plans and on the basis of their experience and imagination to develop comprehensive shop drawings for cabinets. When multiple architects collaborate on a later stage, each of their plans may differ in detail but cabinet or millwork shop drawings help to resolve them. They essentially resolve the conflicts between contractors, architects, and manufacturers right at the design stage.

Ideally, detailed shop drawings for cabinets help the architects align design and dimensions as per their architectural plans. Errors or conflicts due to tolerance or geometrical limits issues can be detected at an early stage. Wall mounted cabinets are the most critical when it comes to dimensions. This is because they fit into the alcoves of the walls and hence need precision manufacturing keeping in center aesthetics of the place. Thus, making detailed and error-free shop drawings is a fundamental need.

Cost consciousness

With advancing features of parametric CAD, shop drawings development has become easier and inculcating more details in the drawings is stress-free for CAD drafters. Furthermore, with detailed shop drawings, manufacturing quality too has uplifted since the design communication between the architects and developers became more efficient.

Secondly, with shop drawings, all the last-minute changes for material substitutes or design upgrades, etc. can be marked in drawings and updated later. These mark-up drawings with approvals are enormously important in verifying an internal request and results in favorable decision making with ready-updated information.

Explaining the details

Shop drawings are very detailed. Many casework drafters prefer to depict information of every single dowel and joinery very minutely. But having extra information causes problems to architects at times. Drawings overloaded with information become too clumsy to handle and pose challenges in quickly extracting information. Such drawings also lead to misinterpretation to manufacturers on the shop floor and misruns occur.

It is, thus, a good practice for drafters to exclude any extra information in the drawings that will save time for all the teams involved in the project. Repetitive information should be replaced with a call out and limit the details as per the consensus.

Final Words

Bottom line is when shop drawings are prepared in collaboration with all the architects, manufacturers and millwork developers, the output is far better in terms of quality and accuracy. Even if the architects or the construction company hires an external CAD drafting company, their knowledge, and experience in the field help in the development of finely drafted and accurately detailed – with the only extremely necessary information – in the cabinet shop drawings.

For more information on casework shop drawings, speak to us at info@hitechengineeringservices.com

Feb 28th, 2024

Feb 28th, 2024

Leave a Reply