Table of Contents

Contractors appreciate you as a sheet metal manufacturer and have always been loyal to you whenever a new order arrives. Your customers too are satisfied with the kind quality of fabrication your shop floor rolls-out and the designs your engineers are developing.

But customers are tired of good products and even the best designs are not being sold. Such issues of increased display life happen frequently in case of architectural ornamental products such as canopies, handrails, roofs or balustrades. Customers want their products to be good in quality but do not want what others can have.

Customers need their customized designs and yet want to maintain the quality. They want to be different, so retailers too are emphasizing on novel designs. With customized demands, sheet metal contractors face challenges meeting the deadlines.

You as a manufacturer will have to ask your building products design engineer to stock every option to manufacture or you will have to convince the retailer to buy only what you have manufactured, leaving a significant number of customers dissatisfied. Both the ways are not very logical for bespoke business needs. And the dilemma makes you feel vulnerable in taking a decision since you will definitely fail in making the ends meet.

Let the customers tell you what they want

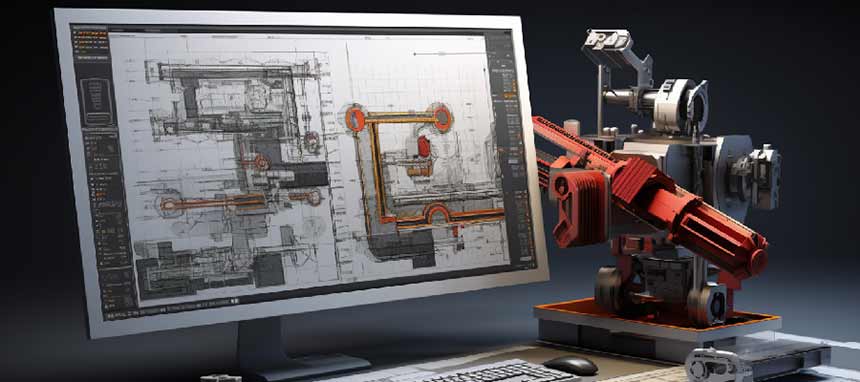

Such situations when have been bothering for long enough without resolution, adopting new technology to make profitable growth is the only way out. And developing product configurator using engineering design automation techniques gives you the new idea of manufacturing only after the point of sales.

Several small-off orders along with low manufacturing volume and high product mix can be addressed swiftly and at ease. You as a manufacturer can differentiate the customer needs for personalization and take it to shop floor.

CAD customization and responding to sales inquiries immediately helps you personalize all the products and expands your horizon in the market as a manufacturer who ‘manufactures products tailored to the customers’ needs.’

Normal Case versus Configured Case

For example, a customer who happens to be a retailer of balustrades and wants you to manufacture a certain number of balustrades each having their own aesthetics. For regular case scenarios, your design engineer will start preparing 3D models and fabrication drawings using CAD platforms and will take more days than expected just for product designing; forget about manufacturing and redesigning in change orders and research.

On the other hand, as mentioned above, if your design engineer has already documented all the possible design variants for handrails, spindles, newels and base rails, fetching one each from many designs will result in quick assembly models of balustrades. And product configurator solves the challenges of time-consuming design tasks.

Online product configurator will automatically ask the retailer to select the choices for the once documented in CAD and uses a logical set of rules for assembly with proper configuration. It then creates a 3D rendered model for retailer’s reference with a sales quote and sends you the final model along with fabrication drawings. Your engineer can extract the necessary information generated automatically, including BOMs, assembly information and other related information.

What are your benefits as a manufacturer?

The best takeaway for you as a manufacturer will be to manufacture products once order for that particular product is placed; and not before that. It implies that you are spared from wasting your material, time and skills upon manufactured goods that remain unsold – which stand as a major threat for architectural ornamental products.

Secondly, since you are not stocking your goods, it reduces warehousing costs which also gives you a better room to set your sales pricing. And most importantly, customers too, find more value in the personalized product. This also makes the retailers and customers of product manufacturing firms/companies to fee that their product is made-to-order, exactly as per the specifications, ultimately enhancing the overall buying experience.

Product personalization: Win-Win Situation

Design automation for product personalization helps in attaining a win-win situation for both, you and your customer. This ‘you’ can be a manufacturer of building products, ornamental products, a smaller industrial appliance such as nails, and the customer can be sheet metal contractor, the retailer for any of these products or an individual user.

If you see yourself in either of these categories, personalizing your product with design automation techniques is the solution, either to sell/manufacture or to purchase/order.

Leave a Reply